At MEB, a crucial aspect of our commitment to safety is the implementation of Safety Lockout Systems, commonly known as lockout/tagout (LOTO) systems.

LOTO systems serve a simple yet vital purpose: they ensure that dangerous machines or electronic devices are effectively shut down and cannot be restarted until maintenance, servicing, or other work is completed.

This involves physically locking the power source of the equipment and attaching a tag to indicate that work is being performed. This proactive approach prevents accidental or unauthorized use of machinery, or a breaker/valve from being turned on, which then minimizes the risk of injury to our team.

At the Nansemond Treatment Plant, collaboration with HRSD is essential for the successful implementation of LOTO procedures. Before any work begins, we communicate with HRSD to ensure that all equipment is properly turned off and tagged out. This may entail multiple locks placed on the same machine or equipment by each contractor and HRSD. Each entity removes their lock only when their work is finished, guaranteeing the safety of all workers involved in the operation.

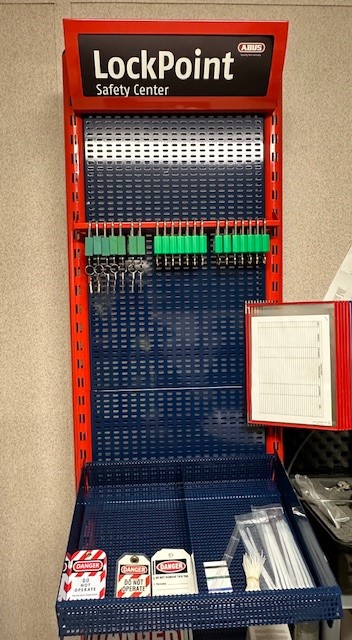

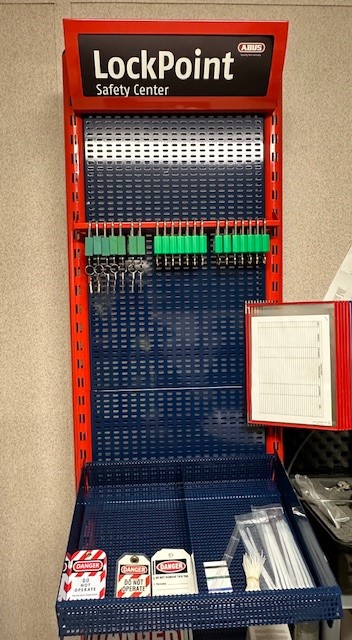

To streamline this process and enhance accessibility, we’ve invested in a “Lockout Center” at the Nansemond Treatment Plant. This houses all our locks, tags, and signage, making them readily available for use. Each lock is uniquely keyed, and accompanying tags display names or companies, along with contact information, facilitating clear communication and accountability.

At MEB, the well-being of our workforce is our top priority. By adhering to the LOTO protocols and having strong collaboration skills with HRSD, we ensure a safe work environment for everyone involved.

>

>

>

>

>

>