2. The exterior shell of the building was also changed from masonry to precast concrete. This was another schedule improvement of multiple weeks but also permitted other trades to work safely in the vicinity of the wall erection. In contrast, masonry would not have permitted the same concurrent workability.

3. The roofing system was modified from bar joists and steel decking to prestressed hollow core planks. This was another schedule improvement but also deleted the need for fireproofing. Fireproofing is a very expensive requirement with structural steel framing. It also would have shut down other work in the vicinity while the fireproofing was being applied.

4. The transition to hollow core planks modified the roof elevations and deleted some roof curbing to provide a more seamless transition from one part of the roof to another.

5. The transition to hollow core planks allowed bridge cranes to change from an underhung arrangement to a top rail-mounted arrangement, which deleted two rooms of supporting structural steel.

6. Another modification to the original design was to transfer some of the interior piping that was run at a high elevation throughout the building and run that same piping underground and meet at common points throughout the building. This change eliminated elevated, low-production work and accelerated the schedule for other trades that would have been waiting on this piping installation.

7. The number of piles at the Offline Storage Tank was reduced by 50% through coordination with the precast tank supplier. This improved the Offline Storage Tank schedule by two months.

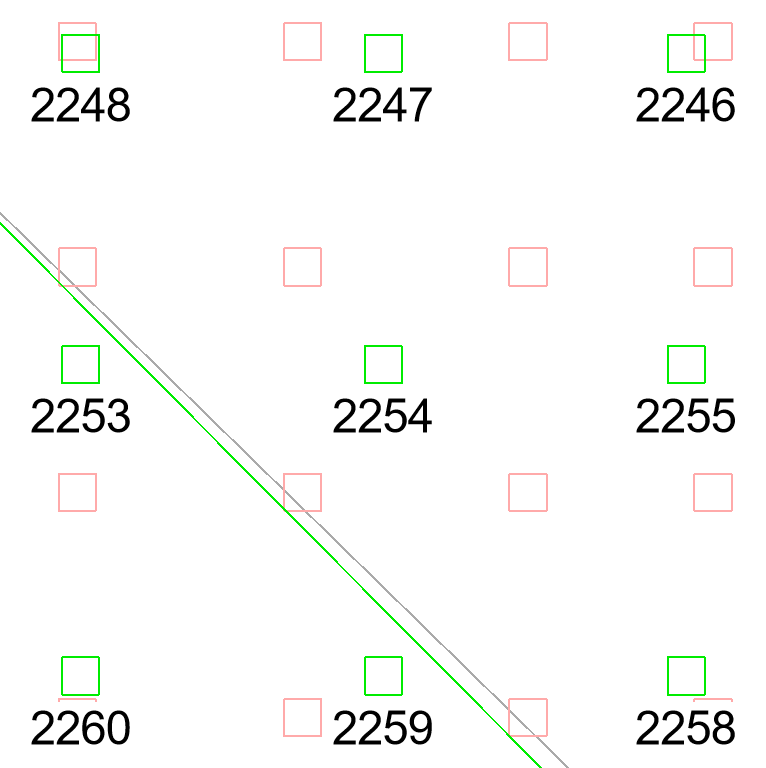

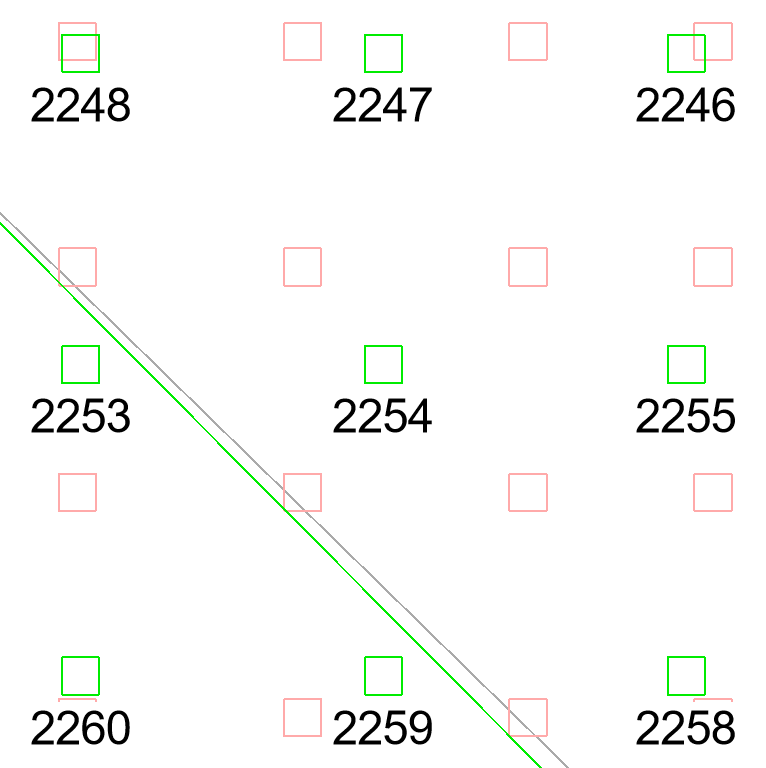

OST – Pile Modifications – The 2D view of the piles represents the typical interior pile spacing and is color-coded with the original layout in light red and the final layout in green. This demonstrates that for a typical 20’x20’ area, the deep foundation design was reduced from (16) piles to (9) high-capacity piles, approximately halving the total number of piles.

8. Anchor embeds have been coordinated with the Offline Storage Tank supplier to increase the efficiency of pipe installation within the precast tank. This will allow for the efficiency of pipe installation to increase by 50%.

The collaborative efforts of MEB, HRSD, and RK&K have yielded substantial schedule improvements early on in the project. While the completion date remains distant, these proactive measures have positioned the project for early completion.