MEB, Bridgeman Civil, and Bradshaw Construction Corporation recently completed a microtunneling operation at the HRSD Suffolk Pump Station project, installing approximately 900 feet of 48″ diameter pipe beneath an active railroad. The work provided a critical underground utility connection while maintaining uninterrupted rail service.

Method and Execution

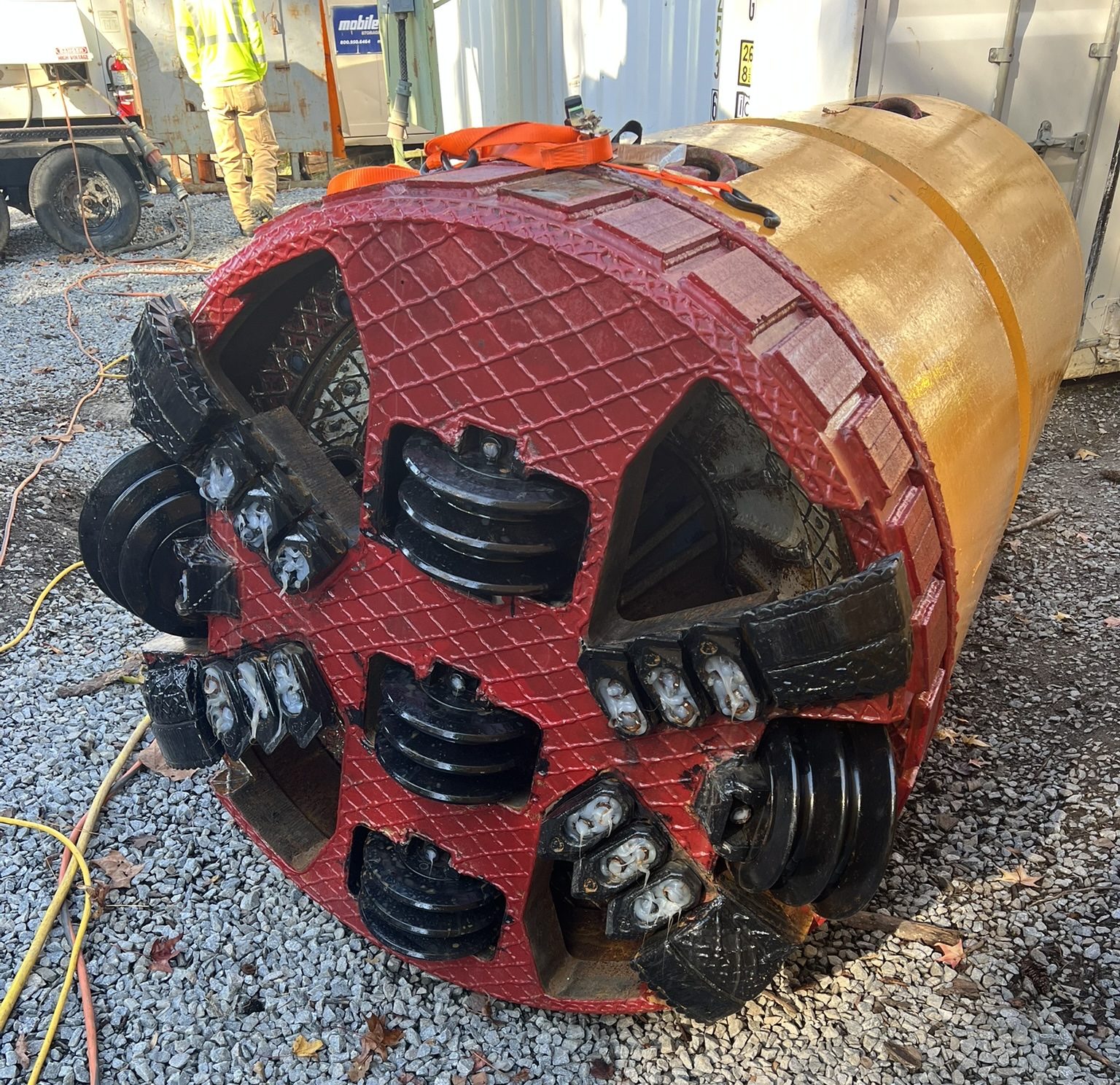

Microtunneling is a remote-controlled, computer-guided tunneling method used to install pipelines with a high degree of accuracy and minimal surface impact. For this project, Bradshaw operated a microtunnel boring machine (MTBM) that advanced at a rate of roughly 1.6 centimeters per minute. The slurry system maintained face pressure to balance groundwater and soil conditions, allowing the team to achieve precise control of line and grade throughout the drive.

>

>

>

>

>

>