Photogrammetry is a method of “reality capture” in which three-dimensional data is generated from a series of 2D images. Using a drone for this process enables quick, ongoing captures of the overall site throughout the project. These 3D scans allow for direct coordination and comparison between the real-world jobsite and the 3D BIM model while also regularly documenting progress on site.

how it works //

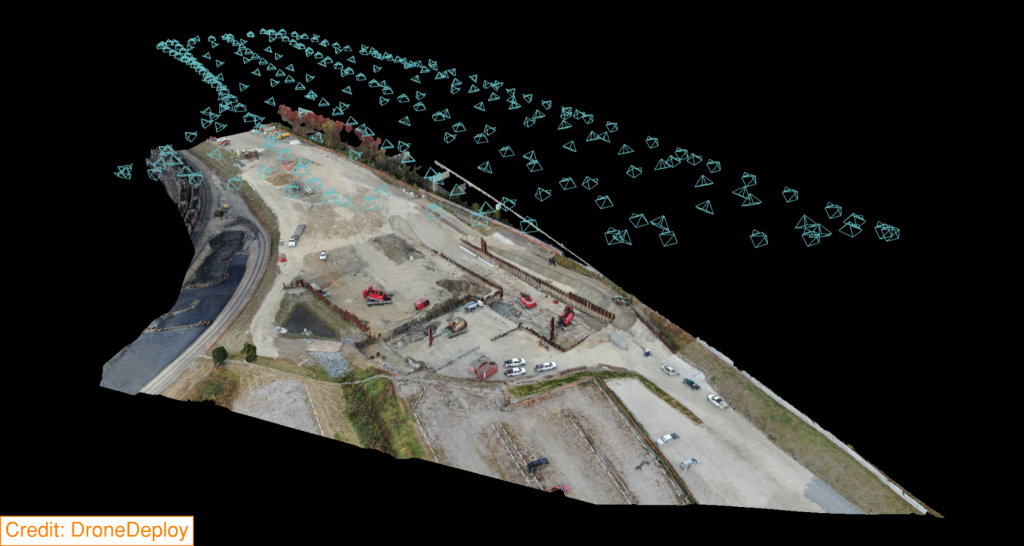

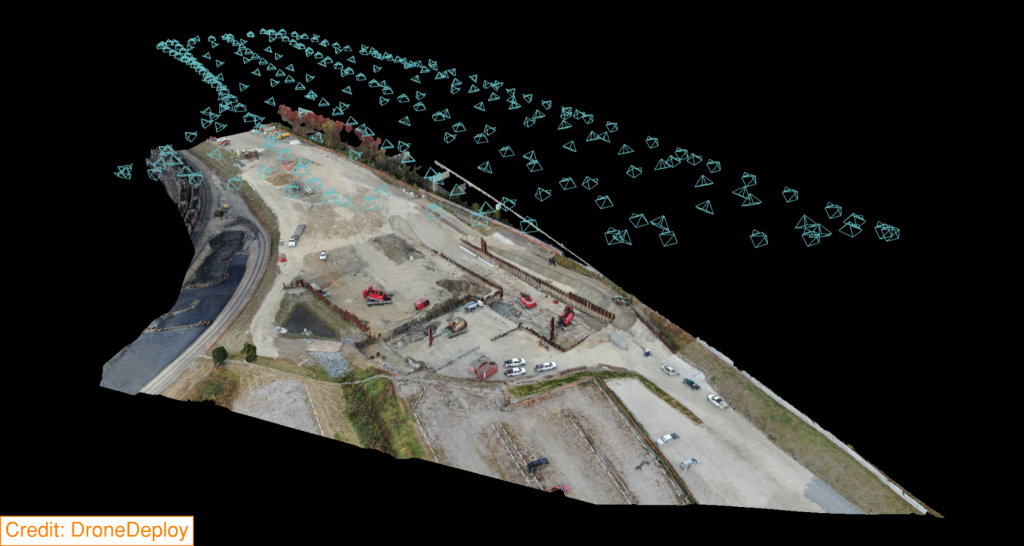

The drone is pre-programmed to fly in a grid pattern over the site. A series of Ground Control Points (GCPs) are laid out on-site using crosshairs that are easily visible in the drone images. The exact coordinates of these GCPs are captured via survey equipment for later use. The drone takes photos approximately every 3-5 seconds, and in this case, it captured over 240 photos of the 9-acre site.

The drone is pre-programmed to fly in a grid pattern over the site. A series of Ground Control Points (GCPs) are laid out on-site using crosshairs that are easily visible in the drone images. The exact coordinates of these GCPs are captured via survey equipment for later use. The drone takes photos approximately every 3-5 seconds, and in this case, it captured over 240 photos of the 9-acre site.  Once the automated flight is finished, the photos get uploaded to a specialized software for processing and alignment to the GCP coordinates, resulting in a geolocated digital copy of the capture area. The results are a 3D “point cloud,” which can be easily viewed and shared online as a snapshot of the project. The scan data can also be exported in a variety of formats, including a 2D “orthomosaic,” which is similar to a satellite view except with a much higher resolution (<1”/pixel).

Once the automated flight is finished, the photos get uploaded to a specialized software for processing and alignment to the GCP coordinates, resulting in a geolocated digital copy of the capture area. The results are a 3D “point cloud,” which can be easily viewed and shared online as a snapshot of the project. The scan data can also be exported in a variety of formats, including a 2D “orthomosaic,” which is similar to a satellite view except with a much higher resolution (<1”/pixel).

These processed photogrammetric scans can also be integrated directly into our geolocated BIM model. This ties the digital representation of the project to the physical project site to ensure that both “worlds” align, enabling us to verify that the BIM model is coordinated with ongoing work and vice versa. This not only provides an additional means of quality control on site but also helps ensure that active BIM coordination accounts for as-built conditions throughout the project.

>

>

>

>

>

>

The drone is pre-programmed to fly in a grid pattern over the site. A series of Ground Control Points (GCPs) are laid out on-site using crosshairs that are easily visible in the drone images. The exact coordinates of these GCPs are captured via survey equipment for later use. The drone takes photos approximately every 3-5 seconds, and in this case, it captured over 240 photos of the 9-acre site.

The drone is pre-programmed to fly in a grid pattern over the site. A series of Ground Control Points (GCPs) are laid out on-site using crosshairs that are easily visible in the drone images. The exact coordinates of these GCPs are captured via survey equipment for later use. The drone takes photos approximately every 3-5 seconds, and in this case, it captured over 240 photos of the 9-acre site.  Once the automated flight is finished, the photos get uploaded to a specialized software for processing and alignment to the GCP coordinates, resulting in a geolocated digital copy of the capture area. The results are a 3D “point cloud,” which can be easily viewed and shared online as a snapshot of the project. The scan data can also be exported in a variety of formats, including a 2D “orthomosaic,” which is similar to a satellite view except with a much higher resolution (<1”/pixel).

Once the automated flight is finished, the photos get uploaded to a specialized software for processing and alignment to the GCP coordinates, resulting in a geolocated digital copy of the capture area. The results are a 3D “point cloud,” which can be easily viewed and shared online as a snapshot of the project. The scan data can also be exported in a variety of formats, including a 2D “orthomosaic,” which is similar to a satellite view except with a much higher resolution (<1”/pixel).