We had a great week at WaterJAM connecting with our industry peers and clients!

Our team showed up in full force at the conference delivering three impactful presentations. If you weren’t able to make it to our sessions, check out the brief overview of each presentation below.

John Thornton, Project Executive // The Race from Disaster to Recovery: Collaborative Project Delivery was the Only Option

John Thornton presented alongside Scott Schiller, Engineering Manager from Rivanna Water and Sewer Authority and Matthew Wimmer, Sr. Associate from Hazen and Sawyer. The group discussed the emergency work that was performed after a catastrophic failure at one of Rivanna Water and Sewer Authority (RWSA)’s pump stations.

John Thornton presented alongside Scott Schiller, Engineering Manager from Rivanna Water and Sewer Authority and Matthew Wimmer, Sr. Associate from Hazen and Sawyer. The group discussed the emergency work that was performed after a catastrophic failure at one of Rivanna Water and Sewer Authority (RWSA)’s pump stations.

As a wholesale provider of water and wastewater treatment services for the City of Charlottesville and Albemarle County Service Authority, RWSA owns and operates a 53 million gallon per day (MGD) pump station located at the Moores Creek Advanced Water Resource Recovery Facility. On January 9, 2024, the Charlottesville area received over 3 inches of rain in 12 hours (on top of oversaturated ground conditions) that resulted in a catastrophic failure of this pump station, resulting in an interruption in the conveyance of more than half the service area’s flow to the plant. Following the hectic establishment of a 55 MGD bypass pumping system to restore service, RWSA began a complicated process of reviewing failure modes and needed improvements, utilizing the expertise and existing facility knowledge of various consultants and vendors. It was a calculated race to get the pump station back into operation and remove the bypass pumping system, where desired outcomes were weighed against the monthly bypass pumping expenses and the lead times associated with the improvements. By taking this collaborative approach to project delivery, we were able to harness each team member’s strengths while successfully fast-tracking repairs and completing the recovery process.

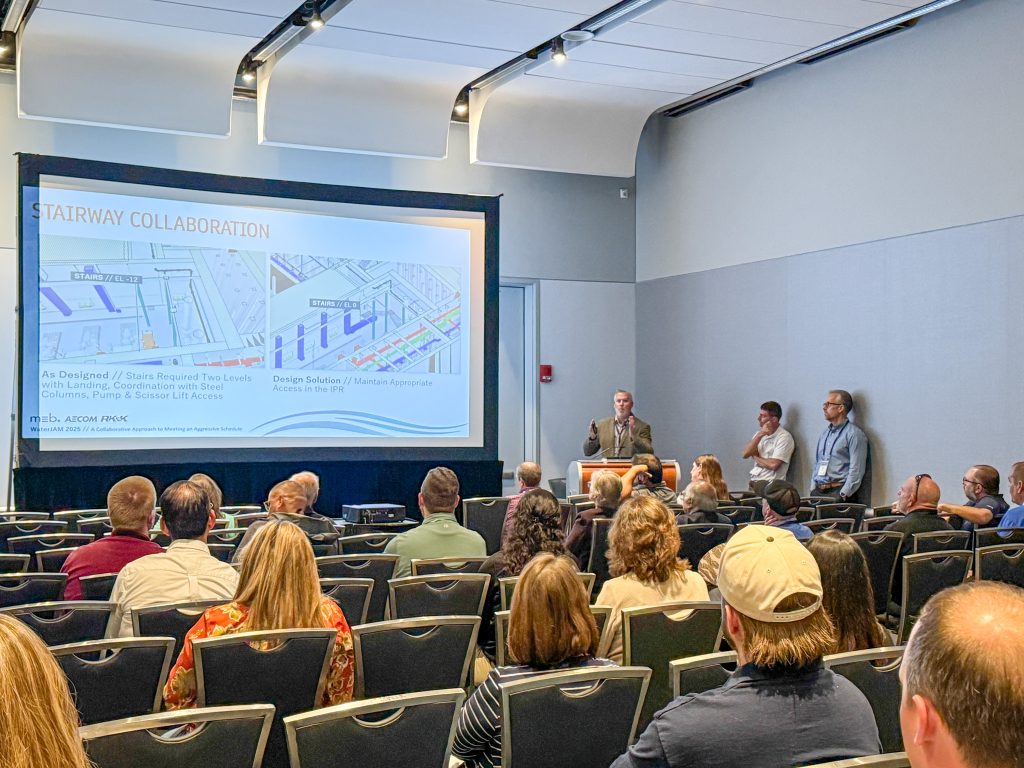

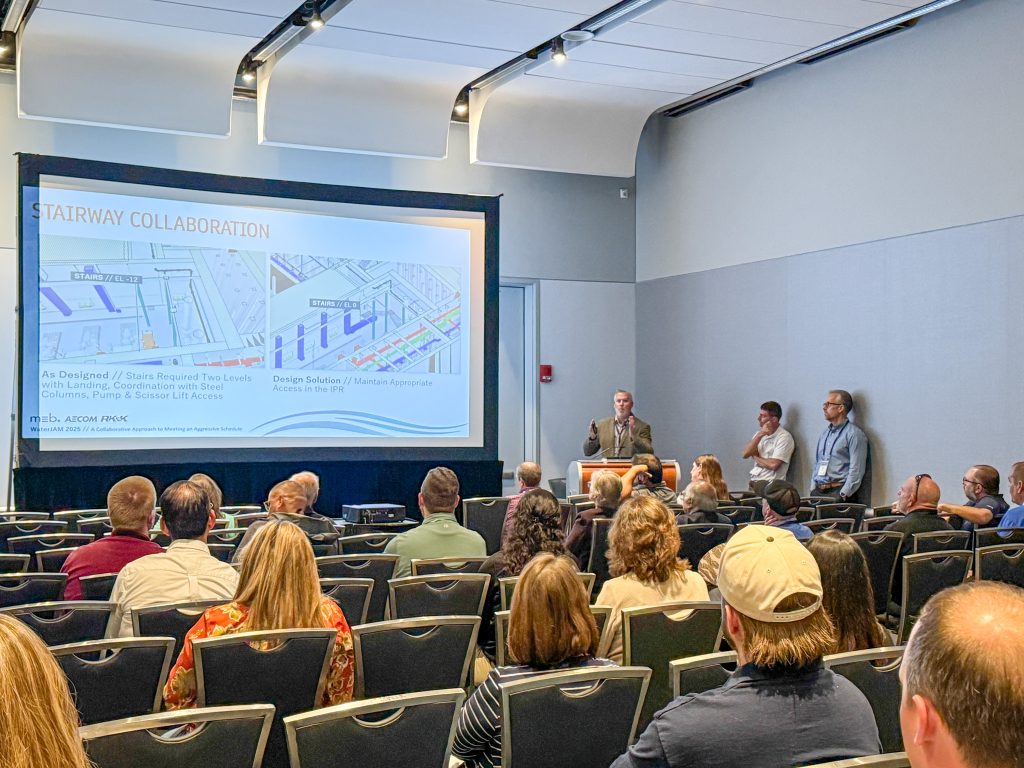

Tim Ratay, Preconstruction Manager // A Collaborative Approach to Meeting an Aggressive Schedule on a Large-Scale Competitively Bid Project

Tim Ratay presented with Kevin Nash, Project Delivery Leader from RK&K as well as David Steele, Project Manager at AECOM on collaborative approaches to an aggressive schedule for the design-bid-build Boat Harbor Pump Station Conversion project. For the construction phase, they focused in on two main collaborative design changes, raising the elevation of an internal staircase and substituting precast wall panels and hollowcore planks for a split-face masonry exterior and bar joist and decking roof system. The changes have ensured an on-time delivery despite the extremely aggressive schedule.

Tim Ratay presented with Kevin Nash, Project Delivery Leader from RK&K as well as David Steele, Project Manager at AECOM on collaborative approaches to an aggressive schedule for the design-bid-build Boat Harbor Pump Station Conversion project. For the construction phase, they focused in on two main collaborative design changes, raising the elevation of an internal staircase and substituting precast wall panels and hollowcore planks for a split-face masonry exterior and bar joist and decking roof system. The changes have ensured an on-time delivery despite the extremely aggressive schedule.

The Boat Harbor Treatment Plant Pump Station Conversion Project faces an aggressive schedule aimed at diverting flow to the Nansemond Treatment Plant and halting treatment at the Boat Harbor Treatment Plant by Summer 2026. The $170M, 3.5-year project has an ambitious schedule to be substantially complete by the end of June 2026 with the new facility in full service. Although the project was procured using the Design-Bid-Build delivery method, the contractor, in collaboration with the engineer and the owner, implemented significant design changes during the initial stages of construction to help achieve this goal, while holding all stakeholders’ interests’ paramount. Construction commenced in June 2023, and the collaborative theme has been present throughout construction to ensure an on-time delivery of the facility.

The Boat Harbor Project is an integral part of the larger HRSD SWIFT Program and close coordination with other projects downstream of the pump station is necessary for project and program successes. The presentation highlighted the following:

- Project purpose and its role in the SWIFT Program

- Design overview – Schedule, logistical and coordination challenges

- Contractor, A/E, and Owner collaboration to meet the aggressive schedule

Zach Emerson, BIM Manager // Using BIM and Drone Photogrammetry on Active Jobsites

Zach Emerson gave an in-depth look into how we are using BIM, Drone Photogrammetry, and Terrestrial Laser Scanning on our active jobsites. He utilized real life visuals to explain the benefits of each application.

Zach Emerson gave an in-depth look into how we are using BIM, Drone Photogrammetry, and Terrestrial Laser Scanning on our active jobsites. He utilized real life visuals to explain the benefits of each application.

Photogrammetry is a method of “reality capture” in which three-dimensional data is generated from a series of 2D images. The use of a drone for this process enables quick, ongoing captures of the overall site throughout the project. These 3D scans allow for direct coordination and comparison between the real-world jobsite and the 3D BIM model while also regularly documenting progress on site. Main areas of focus were:

- How the jobsite scan is captured using a drone

- Integrating the photogrammetric scans into BIM workflows

- Benefits of utilizing drone photogrammetry for the onsite construction team

- Benefits of utilizing drone photogrammetry for the client / stakeholders

Real project examples were utilized from our Boat Harbor Treatment Plant Pump Station Conversion project, the Greater Williamsburg Sports & Events Center project, and the HRSD Nansemond Treatment Plant Struvite Recovery Facility Improvements & Digester Upgrades. Photogrammetry is one of the many examples of how reality capture can be incorporated into BIM to better connect the digital project to the physical world while also strengthening communication between the office and the field, and laser scanning is a powerful tool that enables detailed coordination between existing conditions and new work, among many other applications.

Huge thank you to our team for their time and dedication to their presentations, and to AWWA for another great conference.

>

>

>

>

>

>

John Thornton presented alongside Scott Schiller, Engineering Manager from Rivanna Water and Sewer Authority and Matthew Wimmer, Sr. Associate from Hazen and Sawyer. The group discussed the emergency work that was performed after a catastrophic failure at one of Rivanna Water and Sewer Authority (RWSA)’s pump stations.

John Thornton presented alongside Scott Schiller, Engineering Manager from Rivanna Water and Sewer Authority and Matthew Wimmer, Sr. Associate from Hazen and Sawyer. The group discussed the emergency work that was performed after a catastrophic failure at one of Rivanna Water and Sewer Authority (RWSA)’s pump stations. Tim Ratay presented with Kevin Nash, Project Delivery Leader from RK&K as well as David Steele, Project Manager at AECOM on collaborative approaches to an aggressive schedule for the design-bid-build

Tim Ratay presented with Kevin Nash, Project Delivery Leader from RK&K as well as David Steele, Project Manager at AECOM on collaborative approaches to an aggressive schedule for the design-bid-build  Zach Emerson gave an in-depth look into how we are using BIM, Drone Photogrammetry, and Terrestrial Laser Scanning on our active jobsites. He utilized real life visuals to explain the benefits of each application.

Zach Emerson gave an in-depth look into how we are using BIM, Drone Photogrammetry, and Terrestrial Laser Scanning on our active jobsites. He utilized real life visuals to explain the benefits of each application.